AdaptQ TM

The last step of activating RAFT TM to allow the control to take control of your

resistance welding process is to turn ON the AdaptQ Mode.

RAFT TM

removes the nuisance and time consuming tweaking of weld

schedules due to minor disturbances faced in manufacturing

facilities.

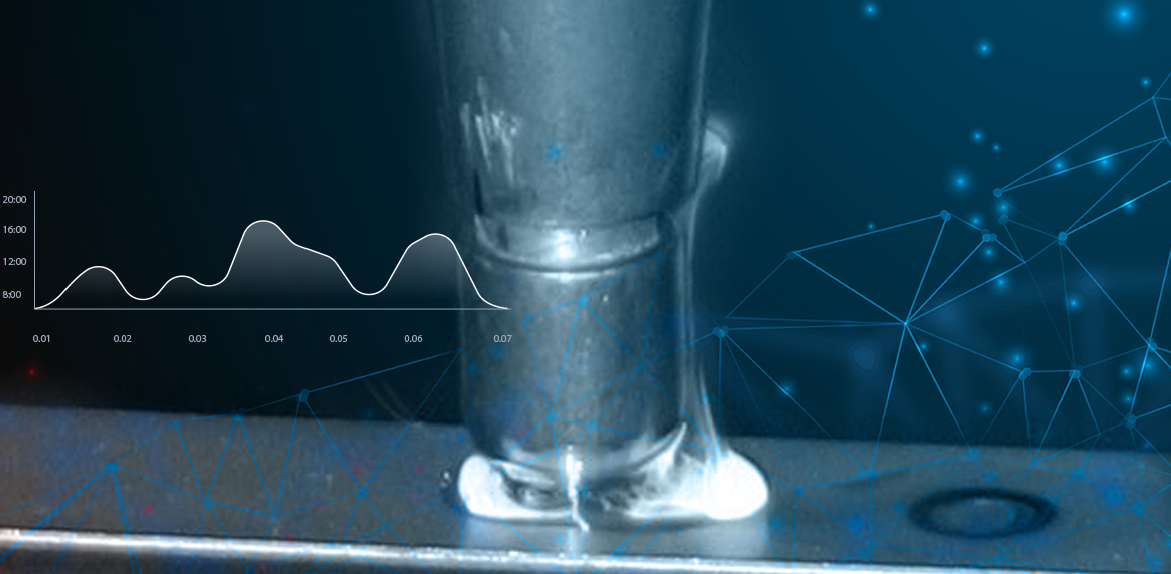

RAFT TM

lends a helping hand in the

resistance welding manufacturing process by

automatically adjusting your constant current program by

adaptively changing current and or time as needed to

overcome weld disturbances.

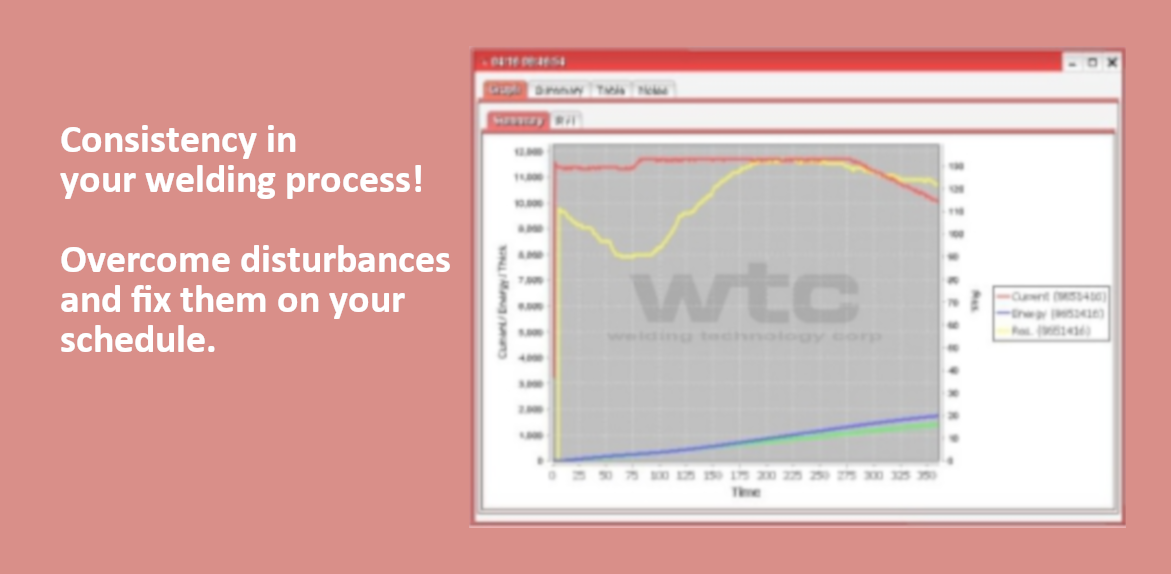

RAFT TM

will maintain

consistency in your welding process and indicate when

secondary tooling needs maintenance.