SoftQ TM

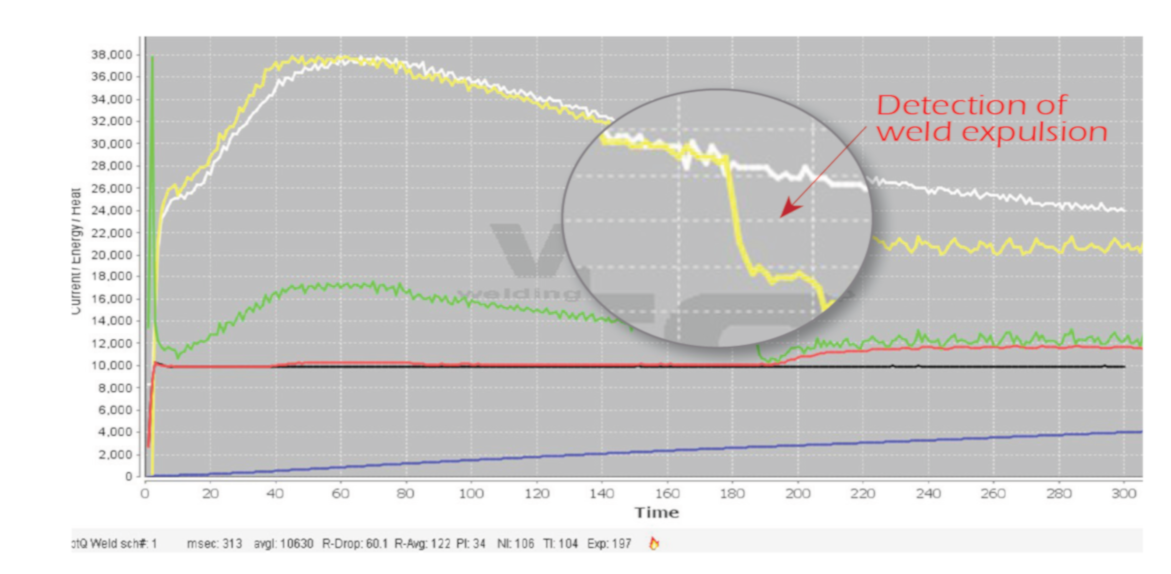

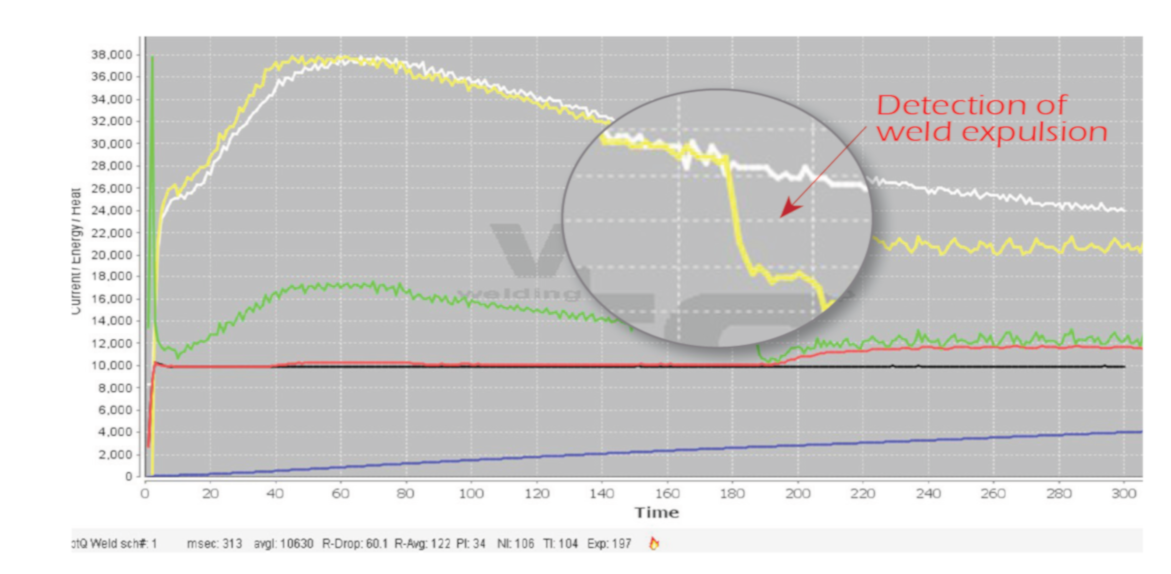

SoftQ TM comprises of quality monitoring tools for post weld data analysis. SoftQ TM works in both constant current and adaptive welding modes.

Monitoring Welding Flash

SoftQ TM comprises of quality monitoring tools for post weld data analysis. SoftQ TM works in both constant current and adaptive welding modes.