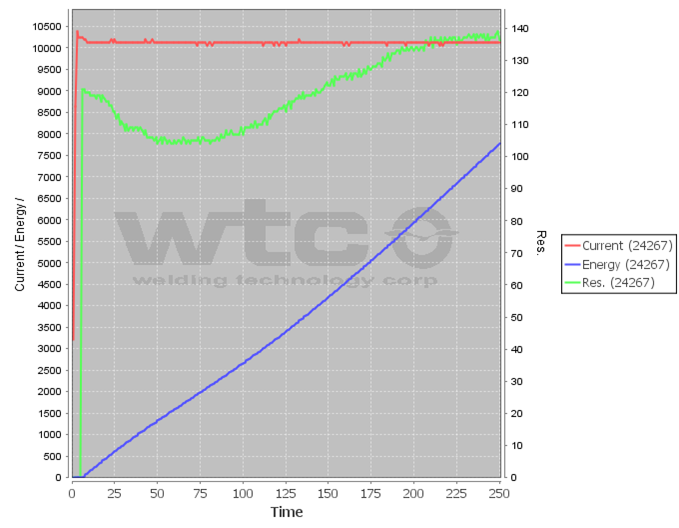

Avoid Producing Missing Welds!

Sometimes there are disturbances that appear

unexpectedly that will cause a missing weld. Even with

desired stable welding currents, the growth of a good

spot weld escapes. In this case shown to the left, the

current is held constant (red line) at about 10k Amps

for 250mS, however the dynamic resistance curve shows

that the weld was never completed. Something drastic

happened such as a shunting path for welding current to

avoid passing through the spot weld location.

You can continue to use constant current and have a tool

in the weld control identify that the weld is

questionable. A tool such as SoftQ will annunciate a

fault because the dynamic resistance signature is not

acceptable.