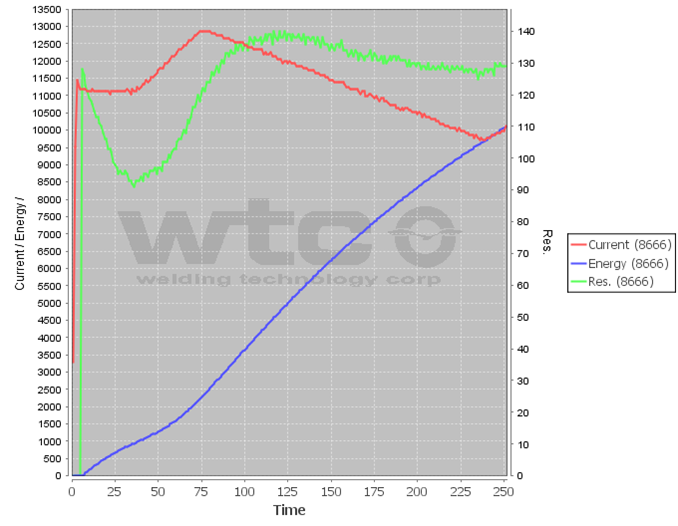

Recovering to Produce Quality Welds

Sometimes there are disturbances that appear

unexpectedly that will cause a missing weld. In this

case, the weld control does not regulate current to be

constant (red line). The control quickly determines that

the resistance curve will not acheive its qualified

profile so automatic adjustments are made during the

production of the weld to recover the process. You can

see here that at approximately 40mS, the current is

increased drastically to try to make the dynamic

resistance peak at a point to assure the development of

a nugget. Then when it detects that this occurs, the

control eventually decreases current to obtain a desired

weld penetration.

A tool such as SoftQ will annunciate a good weld because

the dynamic resistance signature has become acceptable.