Projection Welding |

Projection welding has fewer variables that affect the

resistance welding process as compared to spot welding.

The most important variables of this assembly technique

are the quality of the projections and the response of

the cylinder as the projection collapses during the

welding time.

|

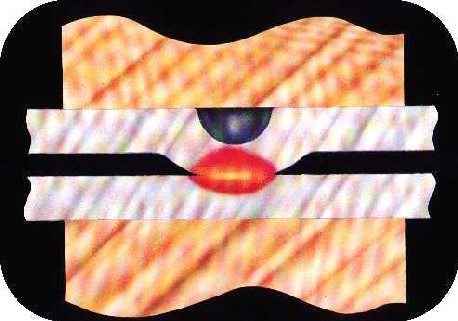

Quality of Projections |

If the cross section of metal in the projection is fractured, the heat build up

will form more rapidly in the stretched material then at the work piece interface area.

This will result in the projection collapsing before fusion takes place. When the projection

is totally collapsed, further growth of a weld nugget will be impossible since the large

surface of the copper electrodes will diffuse current density when the electrodes make full

contact to the work piece.

|

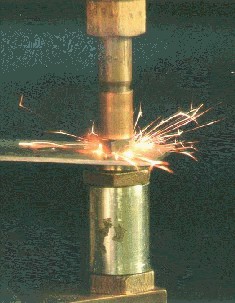

Response of Cylinder Follow Through |

When the projection is collapsing, it is imperative that the electrode force be maintained

otherwise massive expulsion will occur. This expulsion is none other than the projection material

that needs to be fused to the work piece. The cylinder is responsible for follow through.

|

|

Benefits of Projection Welding Techniques |

Projection welding is very easy to maintain if the fundamentals are taken into consideration in

the first place. Steel wire shopping carts, wire racks, and other cross wire products are all projection

welding. Nuts and bolts are often assemble to other metal parts by projection welding. If you want to

produce a part with very little heat surface marks on one side of the panel, then processing a projection on

the alternate part and using large electrodes contoured to the finished part would facilitate the goal.

Good cylinder response that follows through the collapse of the projections on this weld

nut produces very little expulsion and assures good weld quality. |

To Top