Problems and Solutions for Resistance Welding |

The welding control provides tools that will assist welding engineers to improve and maintain quality. All components of the

resistance welding process are important. The mechanical tools must be well designed, the power transfer must be efficient and in good

shape. The control algorithm must be capable of dealing with anomalies. As controls are becoming faster in processing and capable of achieving

thoughtful algorithms, it becomes wise to implement some of these tools into the production environment.

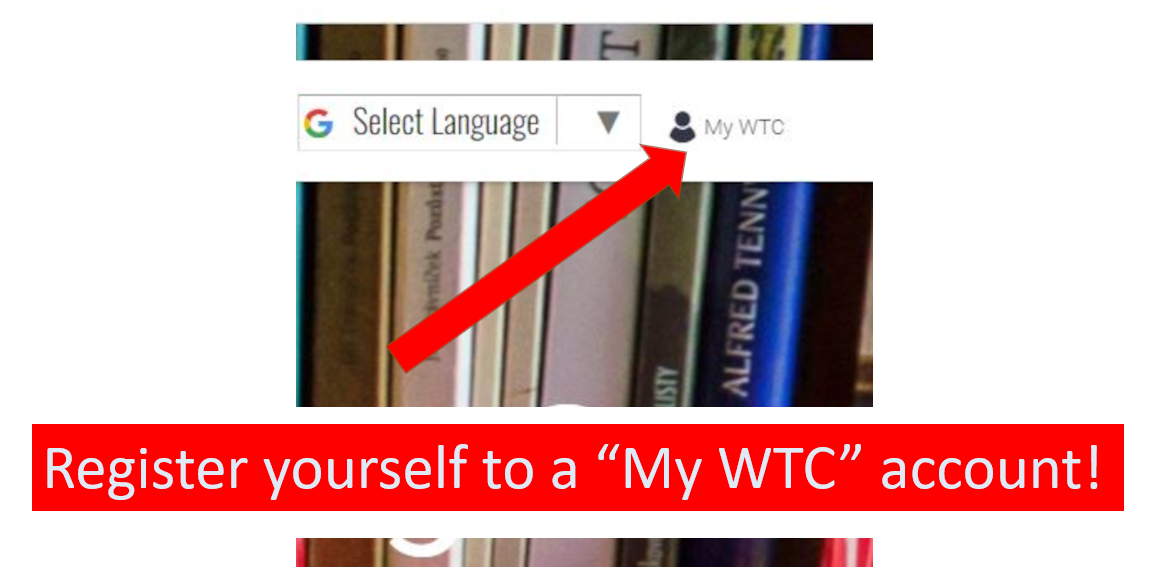

The problems and solutions discussed in this section are very basic and are part of the legacy of WTC's research and controls development. There are much

more tools available that can be reviewed by becoming a member of the "My WTC" group.

|

Typical Problems Occuring in Resistance Welding Processes |

Degradation of welding tools

Welding currents shunting away from weld nugget area

Poor cylinder follow through during welding

Not knowing if the weld nugget is of good quality

Disturbances occuring in unpredictive ways

Want more information? |

Get connected with a "My WTC" user account

Members can get access to more detailed information tailored to specific needs

Get access to file downloads including presentations, manuals, drawings, and more...

How to create an account How to create an account

|

|

|

To Top

How to create an account

How to create an account