Weld MiT

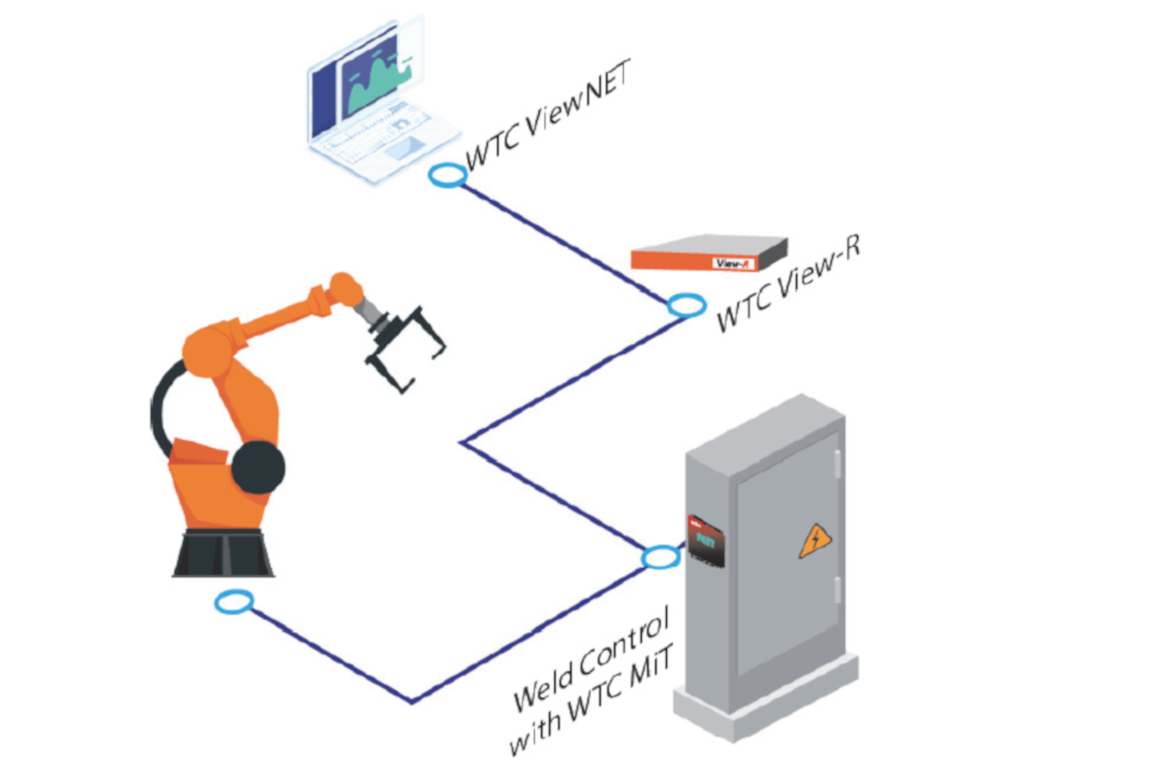

WTC MiT (Measurement Instrument Technology) collects critical

weld data essential for an informed welding quality process.

It is installed as a peripheral device that easily connects with any

robot or weld control. The data collected is stored on WTC

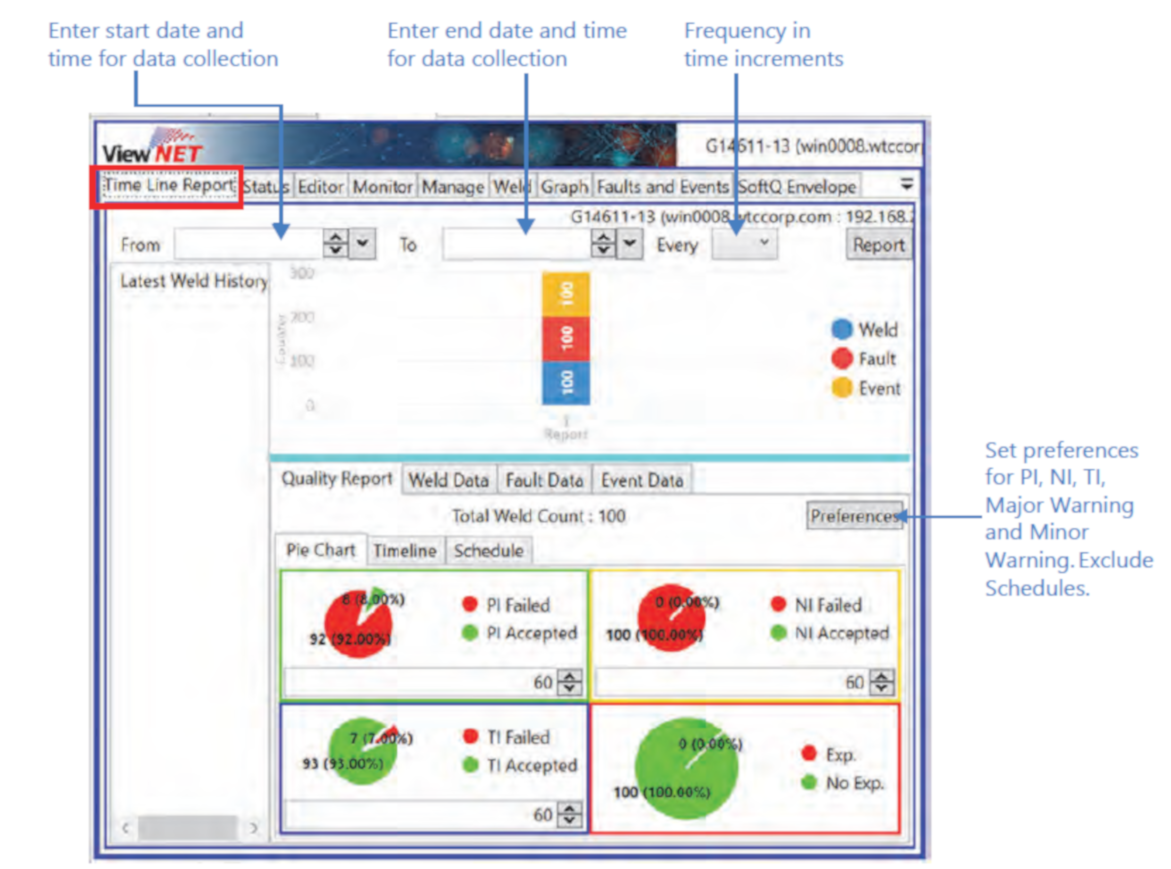

View-R that can be viewed as clear graphical information on

WTC View-NET or RAFT™ Gateway.

This gives the weld engineer

or plant maintenance personnel the ability to monitor every

weld control in the plant from a single interface.

AC and MFDC Weld data detection

AC and MFDC Weld data detection Max / Avg / Min Secondary Current

Max / Avg / Min Secondary Current