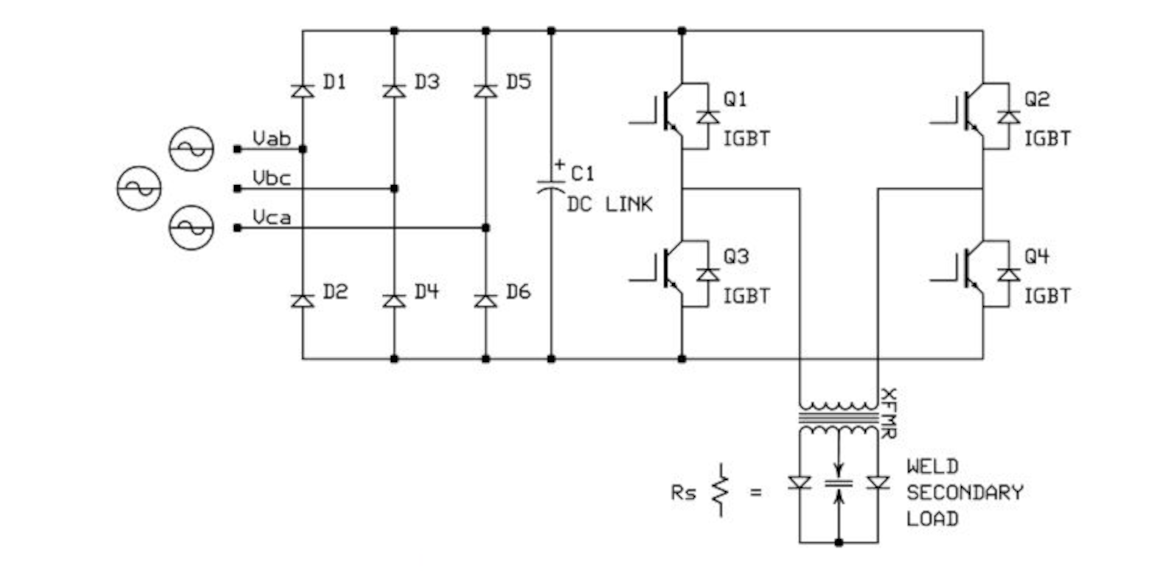

Mid Frequency to DC Controls (MFDC) for Resistance Welding

Since IGBTs are turned ON and OFF by the control system, the algorithms for controlling the welding output are deterministic rather than predictive. The length of time that the IGBTs are left on (pulsewidth) determines the output to the welding transformer.

There are significant advantages for using MFDC systems. During a transition period between the 1980s and the year 2000, much was contemplated as to what these advantages are. One of the first suggestions was of potential energy conservation and associated energy cost savings made possible with the use of MFDC systems. It can be debated that the foremost reason for the wide acceptance of MFDC is due to resistance welding process improvements made possible by using inverters.

To Top