Resistance Spot Welding

Resistance welding is a process for fastening metallic objects together. The metallic objects have various electrical and thermal properties that make it possible for the resistance welding process to occur.

Electrically, metallic objects have some level of resistance to the flow of electrical current. This resistance will cause heat energy as electric current passes through the work piece. The higher the amplitude and duration of current, the higher the heat energy will be produced. This relationship can be expressed in the simple equation:

|

Metal |

Thermal Conductivity (27oC) |

Melting Point |

Electrical Resistivity (Ohms/CMF) (20oC) |

Iron |

0.803 |

1300 oC |

400 ohms |

Aluminum |

2.37 |

680 oC |

17.6 ohms |

Zinc |

- |

435 oC |

22.3 ohms |

Copper |

3.98 |

1115 oC |

10.4 ohms |

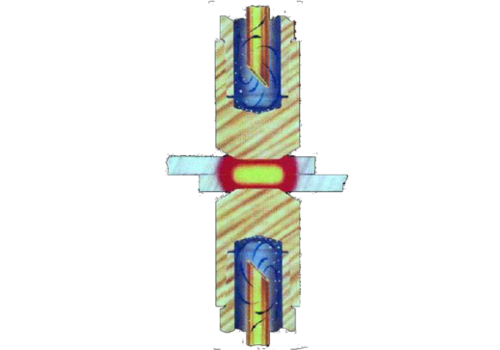

It takes a quantified amount of energy to melt a volume of metal that will produce a weld nugget. Resistance welding is accomplished by passing a controlled density of electrical current (I) through the resistance of the metallic work pieces (R) over a specified amount of time (t).

The welding current is applied via copper electrodes under controlled force. The diameter of the electrode which make contact with the work piece will determine the density of the electric current. The amount of applied electrode force will also affect the resistance across all interfacing layers including the weld nugget zone and the electrode to work piece interface areas. In practice, force is adjusted so that heat is immediately created at the interfacing areas. Whereas it is important to start heat build up at the faying surfaces of the work pieces, it is undesirable to create excessive heat marks at the electrode - work piece interface. It is therefore very important that the electrode cooling system be as efficient as possible to take away heat from the surface of the work pieces that make contact with the electrodes. An efficient cooling system will preserve the electrodes in order to control the current density.

Steel

Resistance welding of steel is relatively easier than welding of aluminum. The characteristics that makes steel easier to resistance weld than aluminum is its higher electrical resistivity and its lower thermal conductivity as compared to the copper electrodes. The cooling of the electrodes is very important since steel requires a build up of temperature in excess of 1300oC to melt which is well above the melting temperature of copper of 1115oC. The flow of water in the electrodes is necessary to take away heat that builds up at the electrode / work piece contact area. This will also help in maintaining the surface contact area of the copper electrodes at a proper dimension which will result in maintaining the current density to melt the steel.

Aluminum

Aluminum has an electrical resistivity and thermal conductivity that is closer to that of copper. What makes it possible for resistance welding is that its melting temperature is much lower than that of copper. Due to aluminum's lower resistivity and higher thermal conductivity as compared to steel, resistance welding aluminum would require much higher levels of current but the weld must be accomplished in much less time.

Coatings on Steel

Characteristics of zinc are shown above to illustrate the approaches necessary to weld coated materials. As compared to bare steel, the coated steels would require a pulse of current prior to the weld to melt the coating. It only requires 435oC to melt the coating. The resistance to the pulse of current by the steel would create the heat that would boil off the zinc coating. Once melted however, the zinc would puddle around the weld zone and would provide lower resistivity as compared to bare steel onto bare steel. Because of this lowered resistivity, significant higher levels of current would be required to weld coated steel as compared to bare steel.

To Top