Three Phase to DC Welding Transformer

The three phase to DC welding transformer is essentially three of the single phase DC weld transformers coupled together on the secondary side after the diodes. There are three separate magnetic cores. The welding control synchronizes the pulse of current for each of the phases into the primaries. The secondary circuits are center tapped and joined together to make the common returns. The outside of the secondary windings are rectified by a set of diodes. The output of the diodes are all joined together to provide the power distribution to the welding tool.

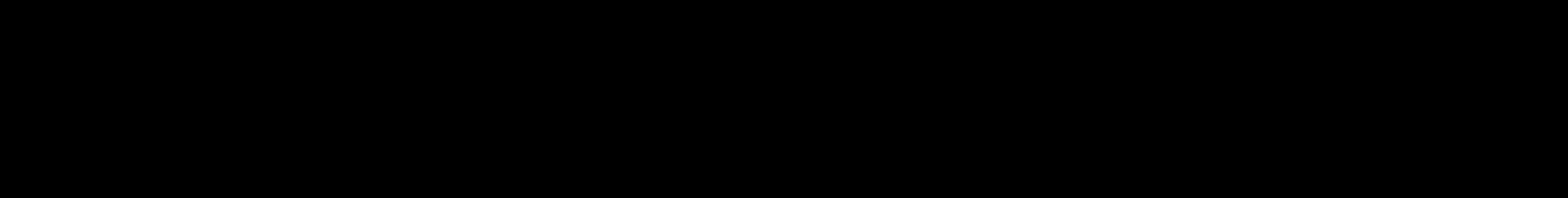

Three Phase DC Current Waveform

The welding control takes care to synchronize the pulses. As shown in the current output waveform,

the control begins by pulsing phase A+, then it will continue with B-, C+, A-, B+, and last C-.Notice in the output curve shown in black line that there is no inter-cycle cooling periods where the current goes down towards zero.