Precursor of RAFT: Contant Heat Control (CHC)

CHC technology was a stepping stone to WTC's RAFT technology.

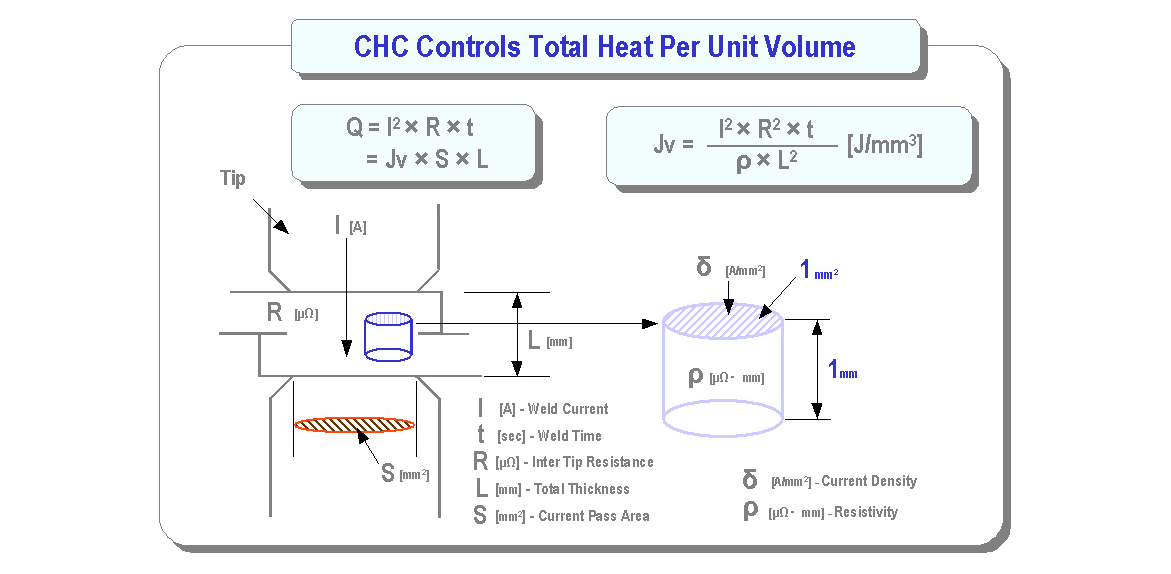

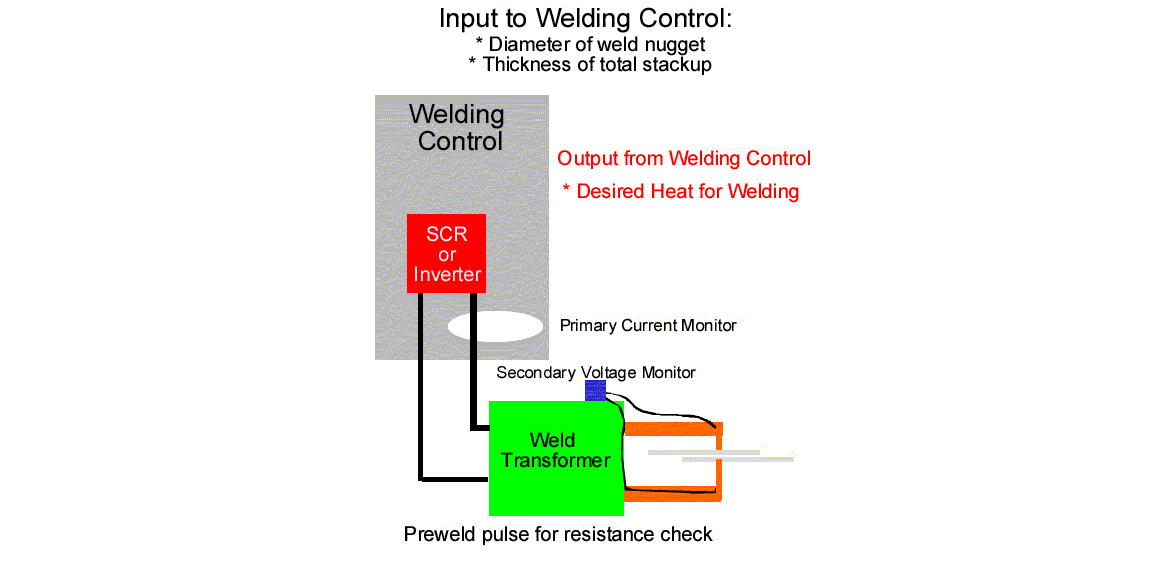

The welding control can monitor heat developed between the electrodes and evaluate if sufficient heat has been applied to melt the metals to develop an acceptable weld nugget. The control is equipped with voltage sensing at the electrodes and current monitoring. The value of these parameters plus the time of current draw will measure "Heat" provided to the welding zone.

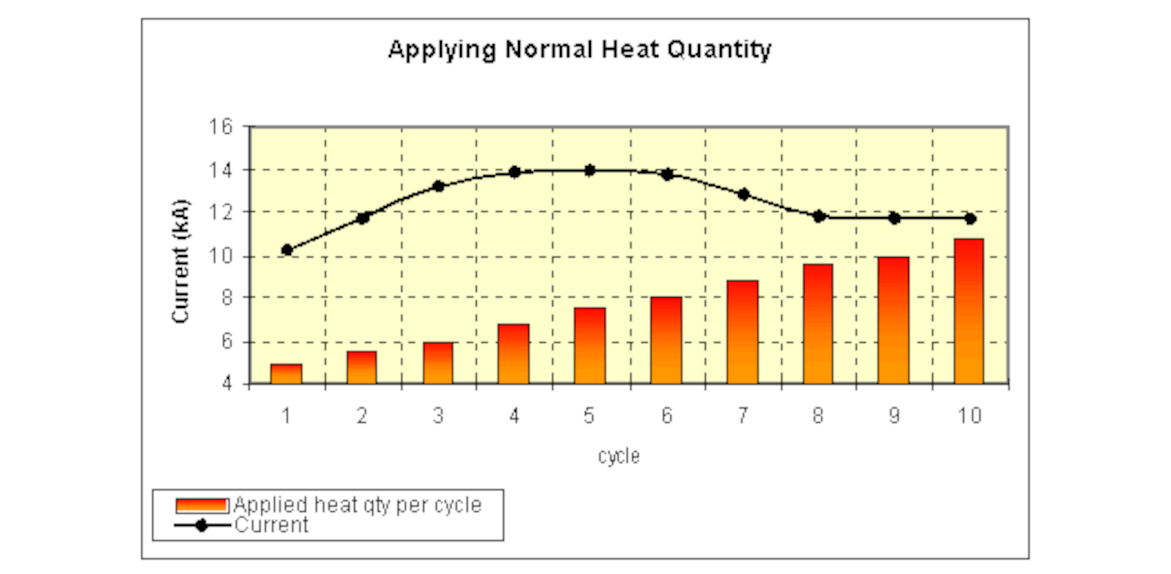

The Constant Heat Control (CHC) Algorithm sought to attain a level of total heat over the entire duration of the weld. The CHC algorithm

seeks to provide equal units of heat over the welding period. In normal welding conditions, the current profile will reflect the dynamic

resistance of the welding nugget. It is given therefore that current does not remain constant during the weld.

There are a number of variables that can affect the behavior of the weld. Some of these include current shunting through adjacent welds, worn electrodes, variations in welding force, coatings on metals, cooling conditions of electrodes, and more. When these variables enter into play to cause change in heat application, the CHC algorithm will increase or decrease welding current in order to yield constant total applied heat. The graph below shows this effect.

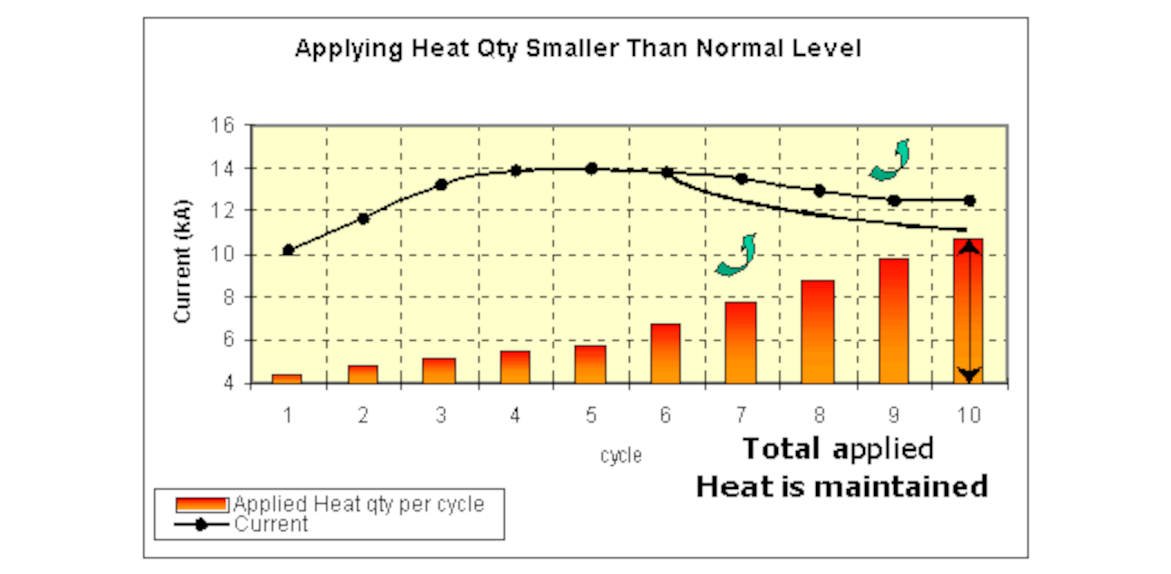

There are a number of variables that can affect the behavior of the weld. Some of these include current shunting through adjacent welds, worn electrodes, variations in welding force, coatings on metals, cooling conditions of electrodes, and more. When these variables enter into play to cause change in heat application, the CHC algorithm will increase or decrease welding current in order to yield constant total applied heat. The graph below shows this effect.

Comparing this chart to the one above, one can see that applied heat is not growing as expected. For example, the chart below shows

that after the 5th cycle of welding current, heat build up has not yet reached the level of normal condition would have reached after

the 3rd cycle of welding current. As a result, the control will increase current in subsequent cycles in order to maintain constant

total applied heat to the weld.

Total applied heat after the 10th cycle of weld is equal to that of the normal condition.

Total applied heat after the 10th cycle of weld is equal to that of the normal condition.

Want more information?

How to create an account

How to create an accountTo Top