Welding Current Shunting Problem

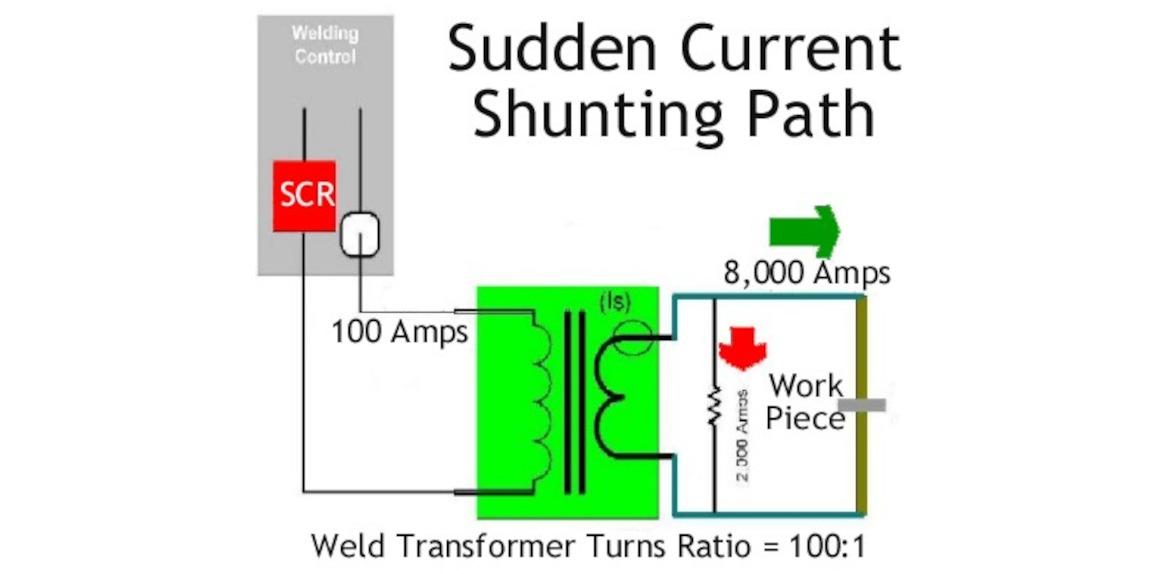

Typically, current monitoring devices are installed on the primary side of the welding transformer and the control translate the value into secondary current by a programmed turns ratio. Even if the current monitoring device is placed on the secondary side of the welding transformer, it is placed in a safe area that will not interfere with the mechanical welding tools.

Shunting paths that can occur typically happen after the monitoring devices. For example, as the welding gun is clamping the work piece, other parts of the gun may make contact with other parts of the work piece causing current to divide itself. In the example above, the weld schedule calls out for 10,000 amperes however only 8,000 amperes goes to the weld area and the other 2,000 finds another path through a shunting condition. The result would be a failed weld. The user would then need to know that this has occurred.

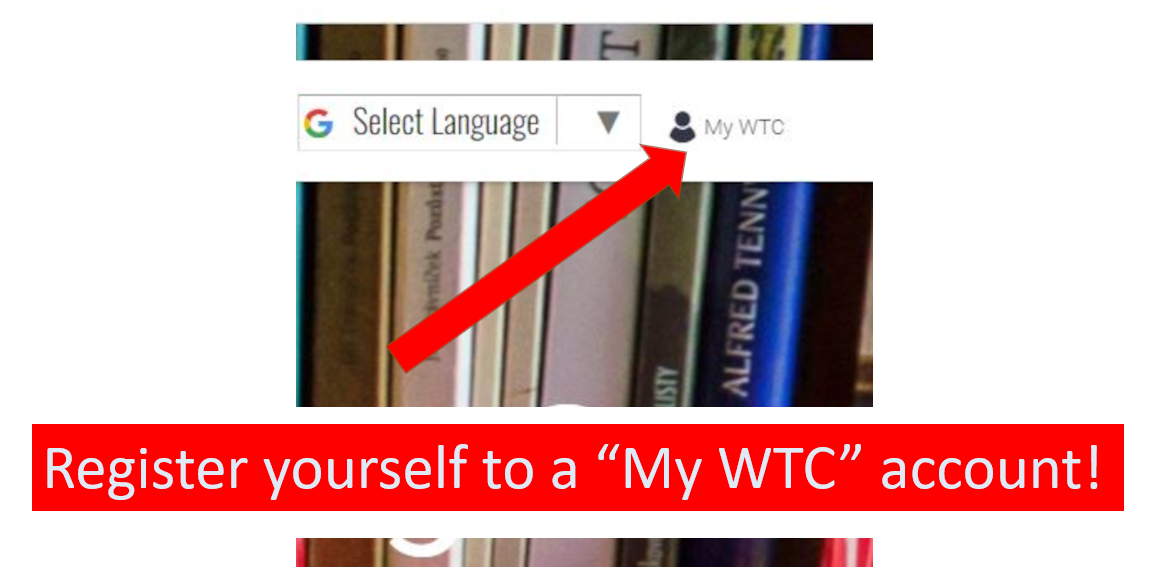

Want more information?

How to create an account

How to create an accountTo Top