Precursor of ForceQ: Thermal Force Feedback (TFF®) System

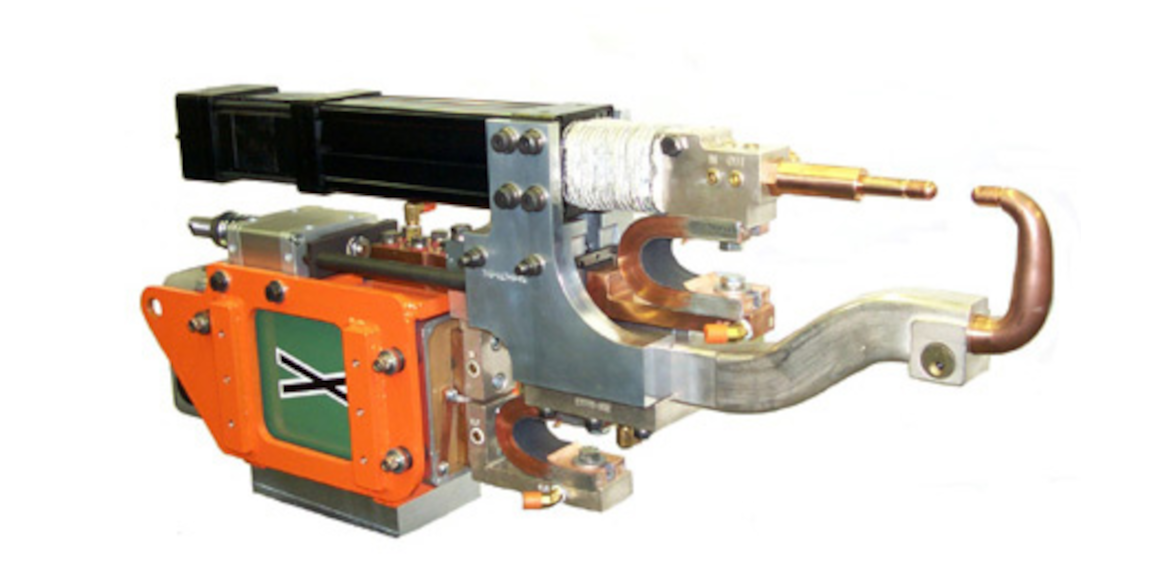

A pioneering technology of the late 20th century, the TFF® system was developed and promoted in the 1990s. TFF monitored and controlled the weld processor to assure production of spot welds that meet specifications. The TFF® system controlled the process from the moment of gun closure through each stage of the weld: i) close gun, ii) build weld force, iii) development of the weld nugget, iv) indentation of electrodes, v) shut off weld current, and vi) open of weld gun.

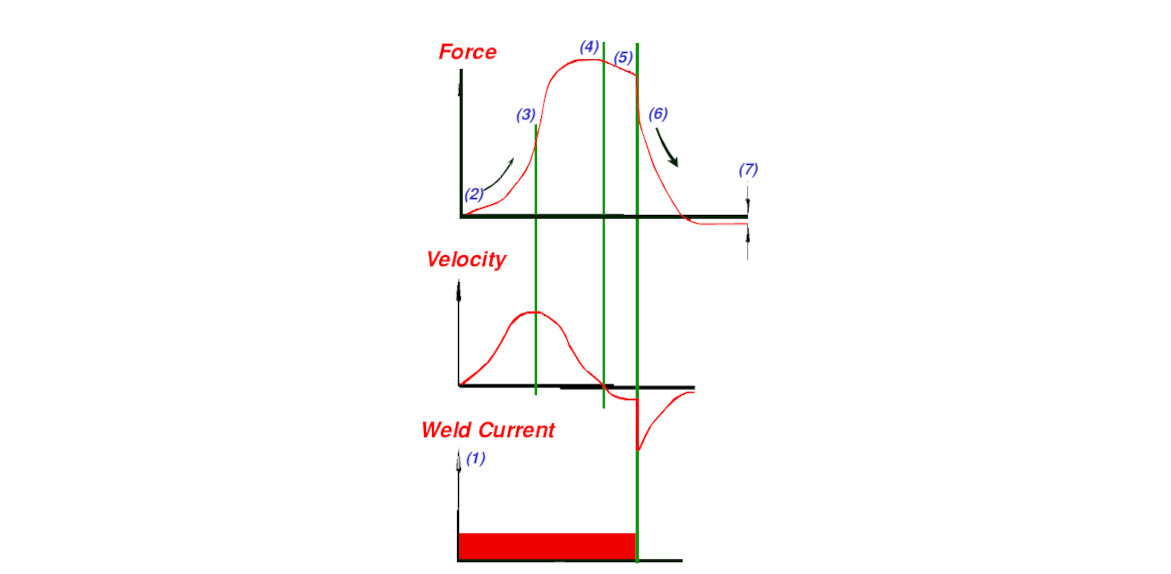

The TFF® monitoring system was based on the physical law that metal subject to heat will expand. If expansion is restricted by physical means, thermal forces will develop proportional to the temperature and the amount of weld expansion.

The TFF® system used the fact that those thermal forces precisely reflected the state of the metal during the welding process. A rapid

rise in thermal forces indicated that the metal is rapidly expanding (2 & 3) A slowdown in the increase in thermal forces showed that the metal had begun

to soften (4) When the increase in thermal force has stopped, the metals have reached the molten state. Then the electrodes indent into the nugget

and fuse the metal pieces. (5 & 6) The TFF® senses the decrease in thermal forces which indicated that indentation had begun, and told the MedWeld 3005 weld control

to stop providing weld current because no further heat is required.

The thermal forces are measured by instrumenting the servo gun between the expanding metal and the mechanical restriction. The algorithm of the servo gun provides the mechanical restriction. The blocking prevents the piston from moving back into the cylinder during the expansion period. This arrangement causes the development of thermal forces, which are monitored by the force sensor. Welding Technology Corp. has modularized the TFF® system for the MedWeld 3000 system. It integrates easily in any permutation of MedWeld 3000 welding control system.

Brochure from Year 2003

Brochure from Year 2003

The thermal forces are measured by instrumenting the servo gun between the expanding metal and the mechanical restriction. The algorithm of the servo gun provides the mechanical restriction. The blocking prevents the piston from moving back into the cylinder during the expansion period. This arrangement causes the development of thermal forces, which are monitored by the force sensor. Welding Technology Corp. has modularized the TFF® system for the MedWeld 3000 system. It integrates easily in any permutation of MedWeld 3000 welding control system.

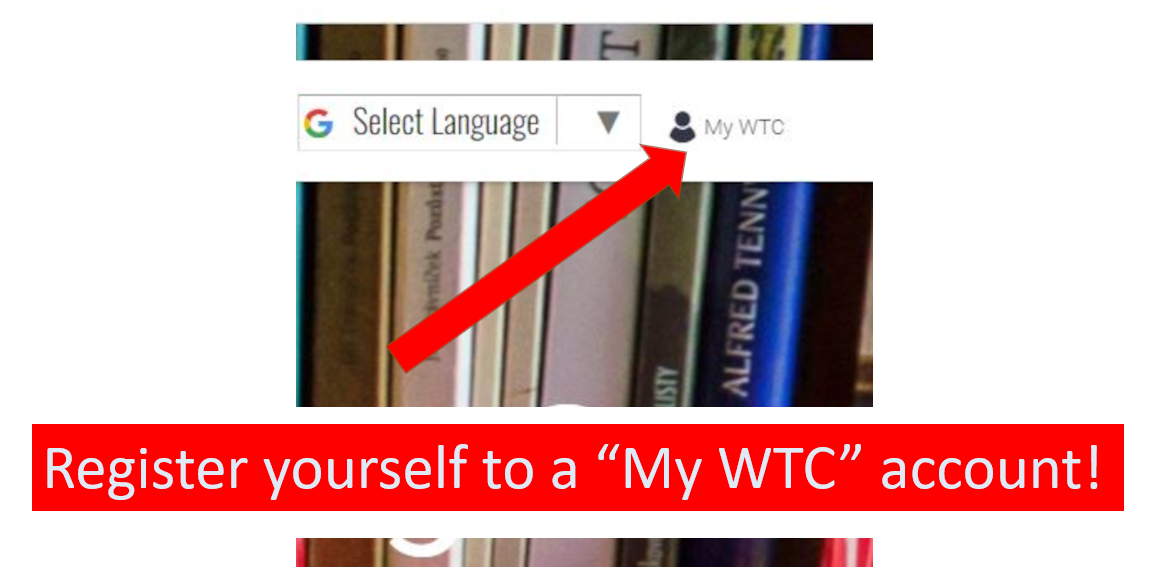

Want more information?

How to create an account

How to create an accountTo Top