How can I tell that the Spot Welds are Good?

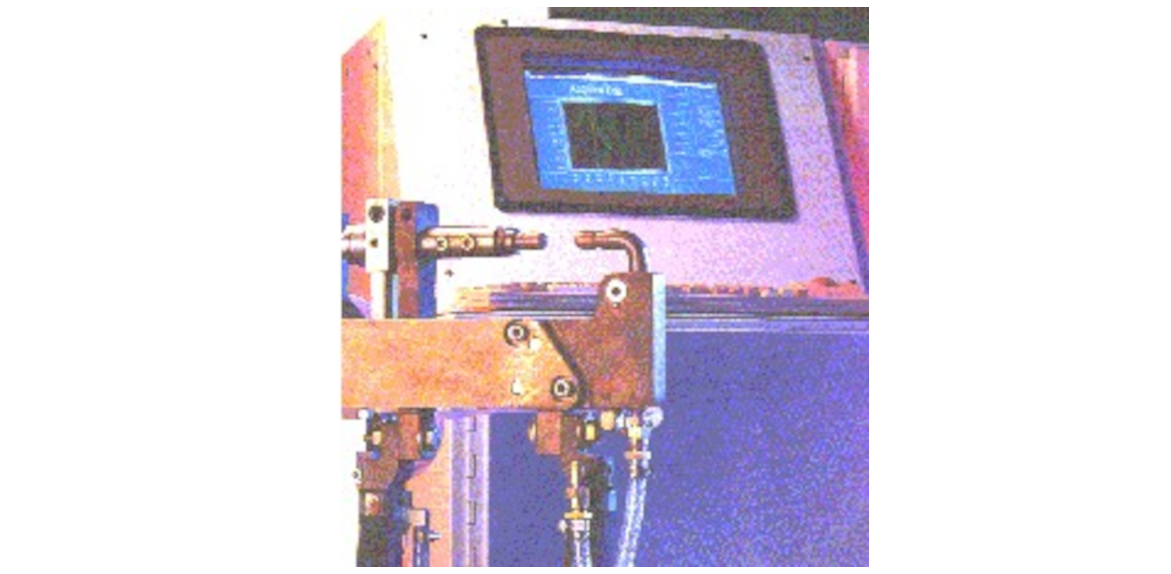

After a spot weld is made, there is no way other than by destructive testing to ensure 100% quality welds. Understanding the basic principles of resistance welding and keeping track of the major variables will enhance confidence of the resistance welding process. If you want to produce spot welds and want to know immediately if the weld is good, you will need to instrument the welding equipment with special sensors to detect the growth of the weld nugget. The sensor will provide input to the weld control to create signatures that model good quality welds.

Several of WTC's legacy divisions have undertaken basic research in the field of obtaining signature analysis of spot welds.

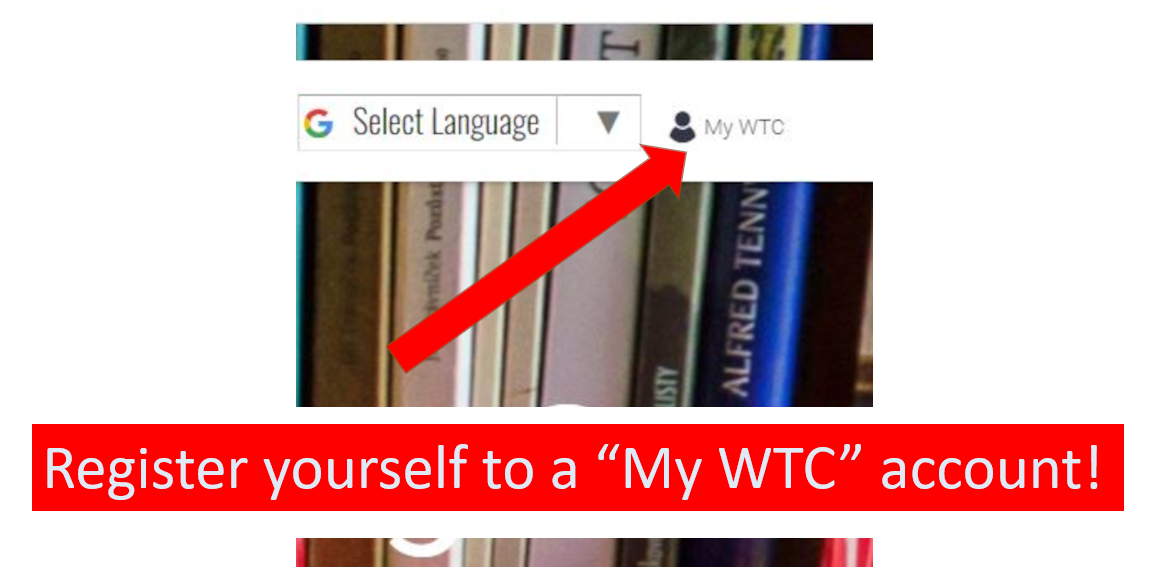

Want more information?

How to create an account

How to create an accountTo Top