Weld Tool Degradation |

A problem that exists for resistance welding process is that the mechanical and electrical characteristics of the tools that furnish welding

current can change over time. This time can be gradual or sudden. Examples of gradual changes are the wearing out of electrical cables or the

corrosion of electrical contacts in the secondary welding circuit. This would be seen as an increase of resistance to current. An example of

a sudden change is the variation of magnetic materials being inserted in the secondary throat which affect the inductive impedance. A specific

example of this would be a large welding gun that does repetitive welds on a part which feeds into the throat of the welding gun. In either case,

the resulting output current will vary.

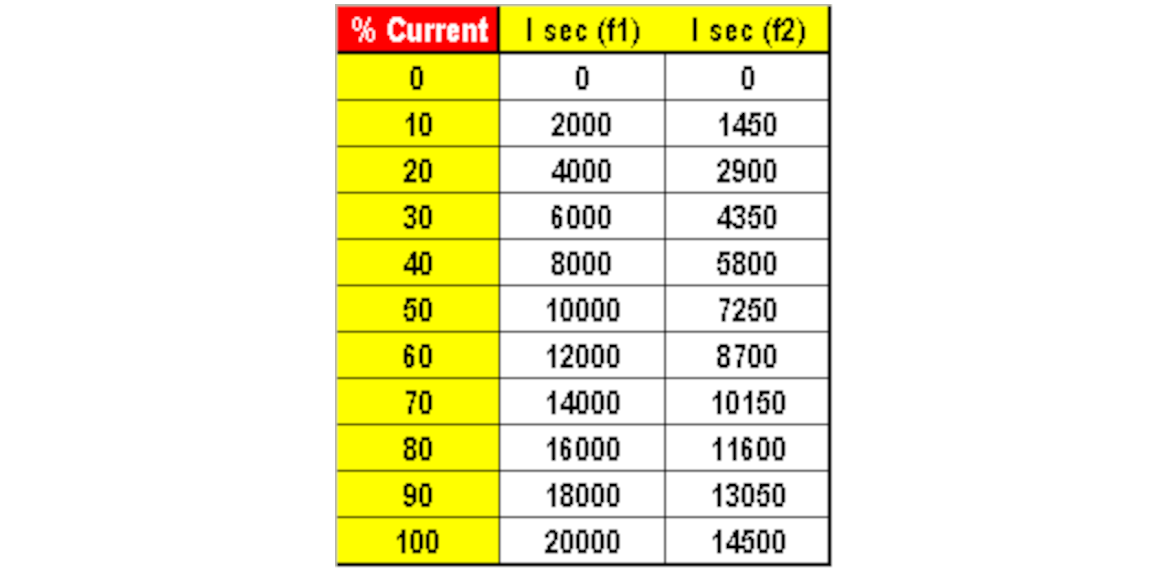

In the table above, you can see what happens to the output if it is programmed to give a percentage of the maximum available current. If in

condition (f1) the maximum available output is 20,000 amperes and we need 10,000 amperes for the weld, the user would program 50% current to

obtain the desired response. If a change is introduced, whether it be gradual or sudden, the same level will yield lower current levels. Condition

(f2) for example would have seen changes in resistive or inductive impedance such that the maximum available output would only by 14,500 amperes.

Therefore if the user is still using the 50% current level, the output would only be 7,250 amperes, which may be shy of producing the desired

weld nugget.

|

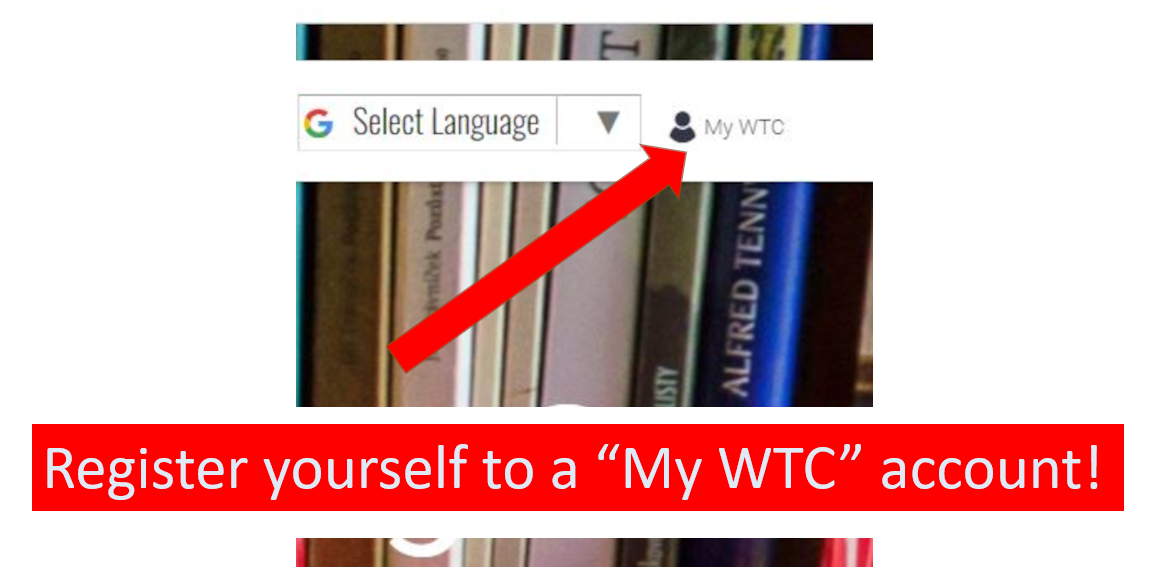

Want more information? |

Get connected with a "My WTC" user account

Members can get access to more detailed information tailored to specific needs

Get access to file downloads including presentations, manuals, drawings, and more...

How to create an account How to create an account

|

|

|

To Top

How to create an account

How to create an account